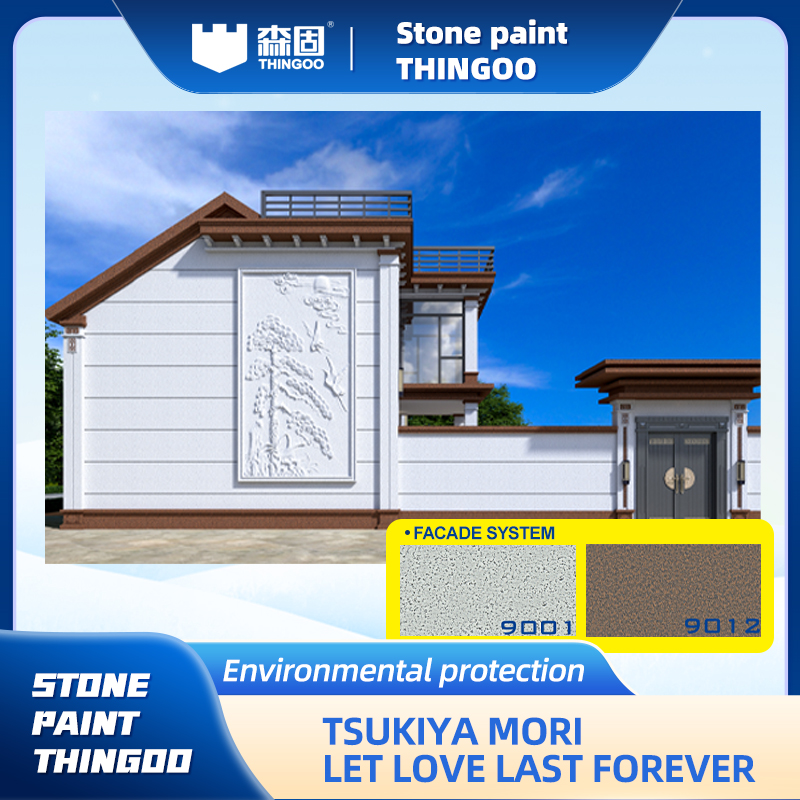

Best Alkoxy Cure Silicone Manufacturers and Suppliers for Quality Solutions

When it comes to high-performance materials, I trust Alkoxy Cure Silicone as the best choice. This silicone offers exceptional durability and flexibility, making it ideal for various applications in the manufacturing sector. Working with Sengu (Shandong) New Materials Co., Ltd., I’ve found them to be a top-notch manufacturer, dedicated to quality and innovation. Their Alkoxy Cure Silicone not only meets stringent industry standards but also provides excellent adhesion and resistance to environmental factors. Whether you’re in automotive, electronics, or construction, this product enhances the reliability of your projects. I highly recommend this silicone for anyone looking to elevate their product line with a dependable and advanced material. Choose this Alkoxy Cure Silicone for your next project, and experience the difference in quality and performance. Trust me, you won't regret it!

Insider Tips For Alkoxy Cure Silicone Products Sets the Industry Standard

In today's competitive market, staying ahead requires not only quality products but also insider knowledge. Alkoxy Cure Silicone Products have emerged as a benchmark in the industry, primarily due to their unique formulation and robust application capabilities. Covering nearly 100 acres, our production base combines cutting-edge research and development with high-efficiency manufacturing. This synergy allows us to create silicone solutions that are not only safe and environmentally friendly but also durable enough to withstand the demands of modern home decoration. What sets our Alkoxy Cure Silicone Products apart is their versatility and resilience. Our team of experts continuously tests and refines our products to meet the highest industry standards, ensuring they perform exceptionally in various applications. As a global procurement manager, you will appreciate our commitment to sustainability without compromising on quality. By choosing our silicone products, you are investing in innovations that promote safer living environments and superior aesthetic appeal for your clientele. Furthermore, we understand the importance of reliable supply chains in ensuring timely project completions. Our comprehensive integration of research, production, and sales allows us to offer tailored solutions for your specific needs, ensuring you receive consistent quality and support. Join us in setting a new standard for home decoration solutions worldwide—discover the difference with our Alkoxy Cure Silicone Products today!

Insider Tips For Alkoxy Cure Silicone Products Sets the Industry Standard

| Tip Category | Insider Tip | Expected Benefit |

|---|---|---|

| Application Techniques | Use a consistent bead size for uniform curing. | Improved adhesion and aesthetic finish. |

| Surface Preparation | Clean surfaces thoroughly with isopropyl alcohol before application. | Enhanced bonding strength. |

| Curing Conditions | Maintain ambient temperature between 20°C and 30°C. | Faster and more complete curing. |

| Storage Tips | Store products in a cool, dry place to extend shelf life. | Preservation of product efficacy. |

| Tool Selection | Use quality dispensing tools for precise application. | Minimized waste and better control. |

10 Essential Tips For Alkoxy Cure Silicone Global Reach Guarantees Peak Performance

N

Noah Carter

Quality is top-tier! I felt valued as a customer due to the high level of service provided by the team.

22 May 2025

A

Anthony Long

Great experience! Both the product quality and the support team were superb.

22 June 2025

P

Piper Turner

Excellent experience! The support team was professional and resolved my issue quickly.

10 May 2025

V

Victoria Banks

Fantastic quality! The customer service was prompt and very helpful, which made the purchase easy.

19 May 2025

M

Milo Green

Impressed by the quality! The support provided post-purchase was outstanding.

08 July 2025

L

Lucy Ruiz

Extremely satisfied with my purchase! The after-sales service was prompt and efficient.

15 June 2025