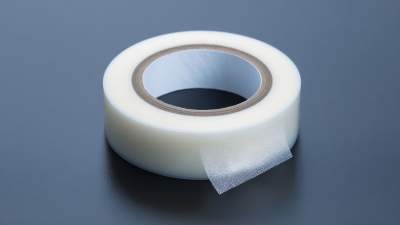

In the realm of adhesive solutions, Single Sided Silicone Tape has emerged as a game-changer, offering unparalleled versatility and performance for various applications. As we look towards 2025, selecting the right tape is crucial for both professionals and DIY enthusiasts aiming for quality and reliability. This article delves into the top five picks of Single Sided Silicone Tape that stand out for their exceptional bonding capabilities, temperature resistance, and ease of use.

Single Sided Silicone Tape is renowned for its ability to adhere to a multitude of surfaces while maintaining durability in challenging environments. Its unique silicone composition allows it to withstand extreme temperatures and deliver long-lasting results, making it an ideal choice for both industrial and residential projects. In the following sections, we will explore the top five products on the market, highlighting their features, benefits, and applications, ensuring that you find the perfect adhesive solution tailored to your specific needs.

When selecting single sided silicone tape for industrial applications, it is essential to consider several key features that can significantly impact performance. One critical factor is temperature resistance. According to industry studies, silicone tape can withstand extreme temperatures ranging from -60°C to 260°C, making it ideal for environments prone to thermal fluctuations. This capability ensures durability and reliability in high-heat applications often found in automotive and aerospace industries.

Another important feature is adhesion strength. Opt for silicone tapes that offer strong adhesion to a variety of substrates, including metals, plastics, and rubber. A recent market analysis revealed that tapes with high shear strength can increase operational efficiency by reducing the frequency of maintenance and replacements. Additionally, consider the tape's chemical resistance, particularly in environments where exposure to oils, solvents, or other chemicals is common. Reports indicate that silicone tapes maintain their integrity even when subjected to harsh chemicals, further enhancing their value in industrial settings.

Tips:

The market for silicone adhesives is poised for significant growth, reflecting broader trends in various adhesive and sealing technologies. By 2025, the global adhesive, sealant, and silicone market is projected to expand to approximately $65.87 billion, with an estimated compound annual growth rate (CAGR) of 4.6% through 2034. This growth is largely driven by increased demand in sectors such as construction, medical, and automotive applications, where silicone’s unique properties offer enhanced performance and reliability.

Particularly noteworthy is the rising prevalence of diabetes, which is fueling demand for medical tapes and adhesive solutions in healthcare. For instance, Germany's medical adhesive tape market, valued at $494.8 million in 2024, is anticipated to grow at a CAGR exceeding 5.3% through 2034, driven by evolving medical needs. Similarly, China's medical tape sector is expected to grow from $451.4 million in 2025 to $801.2 million by 2034, indicating a strong market trajectory. As industries increasingly recognize the versatility and effectiveness of silicone adhesives, their application will expand, propelling market growth well into the next decade.

When it comes to adhesive solutions, the choice between silicone tape and other types of adhesive tapes can significantly impact the outcome of your project. Silicone tapes are renowned for their exceptional adhesion strength and durability, especially in high-temperature applications. Unlike traditional adhesive tapes that may weaken over time or under stress, silicone tape maintains its integrity, offering superior performance in various environmental conditions.

Tips: When selecting adhesive tape, consider the specific requirements of your project. If you need a tape that can withstand extreme temperatures or provide a waterproof seal, silicone tape is often the best option. However, for lightweight applications or temporary fixes, other options like vinyl or masking tape might suffice. Always test your adhesive on a small surface to ensure compatibility and performance.

Furthermore, while comparing adhesion strength, it’s essential to note that silicone tape’s unique properties allow it to bond not only to metals and plastics but also to irregular or textured surfaces. This versatility sets it apart from many other adhesive tapes, making it an invaluable tool in both industrial and home settings. Don’t underestimate the importance of selecting the right tape for your needs; a small investment in quality adhesive can save time and resources in the long run.

Single sided silicone tape is gaining traction across numerous industries due to its unique adhesive properties and versatility. Notably, the automotive sector has found immense utility in this type of tape for various applications, including interior mounting and exterior weather sealing. Its ability to endure extreme temperatures and resist moisture makes it an ideal choice for automotive components, ensuring durability and performance.

In the electronics industry, single sided silicone tape is used for insulating and protecting sensitive components. The tape not only provides strong adhesion but also exhibits excellent thermal management properties. This is crucial for devices that generate heat, as it helps maintain optimal performance while preventing damage to fragile parts.

Tips: When selecting single sided silicone tape, consider the temperature range and environmental conditions of your application. Always test a small piece before committing to a larger project to ensure compatibility with the surfaces involved. For specific applications, such as in electronics or automotive parts, seek specialized formulations that may enhance performance. Lastly, remember to check the thickness of the tape to match the requirements of your project, as a thicker tape may offer better cushioning and protection.

When it comes to adhesive solutions, customer satisfaction is paramount. Understanding key performance metrics can help manufacturers tailor their products to meet the needs of consumers.

Top-rated single-sided silicone tapes excel not only in adhesion strength but also in usability, which is a crucial factor that influences customer satisfaction. Metrics such as ease of application, clean removal, and resistance to temperature fluctuations play a significant role in how customers perceive the quality of these adhesives.

Furthermore, feedback from users reveals that durability and versatility are also essential attributes. Consumers often seek products that can withstand various environmental conditions without compromising their adhesive properties. This calls for manufacturers to continuously innovate and improve their offerings. By focusing on these key performance metrics, companies can ensure that their single-sided silicone tapes meet and exceed customer expectations, thereby fostering brand loyalty and enhancing overall satisfaction in the marketplace.