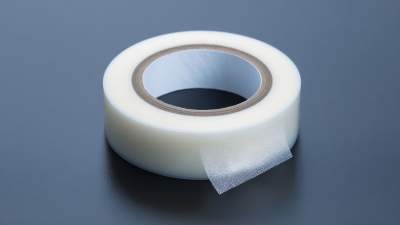

In the ever-evolving landscape of industrial applications, the importance of reliable and effective materials cannot be overstated. One such material that stands out is Single Sided Silicone Tape. Known for its superior adhesion, heat resistance, and versatility, this type of tape is revolutionizing the way industries address their bonding and sealing needs. From electrical insulation to automotive components, Single Sided Silicone Tape offers unique advantages that enhance performance and longevity.

In this blog, we will explore the key benefits of incorporating Single Sided Silicone Tape into your operations, while also discussing top strategies for effectively utilizing this innovative product to meet various industrial requirements. Whether you're looking to improve production efficiency or enhance product durability, understanding the potential of Single Sided Silicone Tape is essential for staying competitive in today's market.

Single sided silicone tape is rapidly gaining recognition in various industrial applications due to its unique properties. One of its primary benefits is its exceptional temperature resistance, which makes it suitable for environments that experience extreme heat or cold. This attribute is crucial in industries such as aerospace and automotive, where components may be subjected to significant thermal stress. Additionally, the tape is highly flexible, allowing it to conform to irregular surfaces and ensuring a secure bond.

When using single sided silicone tape, keep in mind a few tips to maximize its effectiveness. Always ensure that the surface is clean and dry before application to promote optimal adhesion. Also, consider the thickness of the tape based on your specific needs; a thicker tape provides better insulation and durability for heavy-duty applications. Finally, store the tape in a cool, dry place to maintain its integrity over time.

Another advantage of single sided silicone tape is its chemical resistance. This makes it ideal for tasks involving exposure to oils, solvents, and other harsh substances. By using this tape, industries can maintain the integrity of their products while minimizing the risk of deterioration. For best results, measure and cut the tape accurately to ensure a proper fit, thereby enhancing its overall performance across various applications.

Single sided silicone tape has become increasingly popular in various industrial applications due to its unique properties that set it apart from other adhesive solutions. One of its standout features is its exceptional temperature resistance, which can endure extreme temperatures ranging from -40°C to 230°C. According to a report by the Adhesive and Sealant Council, this temperature stability makes silicone tape ideal for automotive and aerospace industries, where thermal extremes are common.

Single sided silicone tape has become increasingly popular in various industrial applications due to its unique properties that set it apart from other adhesive solutions. One of its standout features is its exceptional temperature resistance, which can endure extreme temperatures ranging from -40°C to 230°C. According to a report by the Adhesive and Sealant Council, this temperature stability makes silicone tape ideal for automotive and aerospace industries, where thermal extremes are common.

Moreover, the tape offers excellent durability and adhesion to a range of substrates, including metals, plastics, and glass. Industry data shows that single sided silicone tape maintains strong bonds even in high-moisture environments, significantly reducing the risk of adhesive failure. Additionally, its non-corrosive nature is highlighted in the International Journal of Adhesion and Adhesives, which states that silicone tape does not damage sensitive surfaces, making it an essential choice for electrical insulation applications.

The flexibility and stretchability of single sided silicone tape also contribute to its usability. It can be easily manipulated to fit complex shapes and surfaces, which enhances its effectiveness in production lines. These key features collectively underscore why single sided silicone tape is becoming a go-to solution for many industrial needs, driving efficiency and reliability in manufacturing processes.

Single-sided silicone tape is gaining traction in manufacturing due to its unique properties that enhance efficiency across various applications. One major advantage is its excellent thermal resistance, allowing it to withstand extreme temperatures often encountered in industrial settings. According to a report by the Adhesive and Sealant Council, products that can endure temperatures from -60°C to 260°C will not only increase operational longevity but also reduce maintenance costs by minimizing the need for frequent replacements.

Another significant benefit of single-sided silicone tape is its superior adhesive strength, which promotes quick and reliable bonding of materials. Research from the Flexible Packaging Association indicates that industries utilizing high-performance adhesives saw a 30% increase in throughput due to fewer disruptions in workflows. Moreover, the tape's ability to provide insulation and cushioning without leaving residues ensures a cleaner, more efficient production environment. These qualities not only streamline manufacturing processes but also contribute to overall cost savings, making single-sided silicone tape an invaluable asset for modern industry.

Single sided silicone tape has gained considerable traction across various industries due to its unique properties and versatile applications. For instance, in the electronics sector, the increasing demand for high-temperature resistant materials has led to a rise in the use of silicone tape. According to a report by MarketsandMarkets, the global adhesive tapes market is expected to reach $75.46 billion by 2026, with silicone adhesive tapes playing a critical role, particularly for insulating and protecting sensitive components in devices subjected to extreme conditions.

In the automotive industry, single sided silicone tape is utilized for sealing, insulation, and mounting applications, ensuring durability under challenging environments. The International Journal of Engineering Research & Technology highlights that the adhesives market in automotive applications alone is projected to grow at a CAGR of 4.6% through 2025. The high-performance characteristics of silicone tape make it ideal for bonding glass, metal, and plastics, thereby optimizing production efficiencies and enhancing vehicle longevity. Furthermore, healthcare applications have seen a surge in the use of single sided silicone tape for wound care and medical device assembly, owing to its hypoallergenic properties and excellent conformability. According to a report by Grand View Research, the global medical tape market is projected to reach $10.46 billion by 2025, underscoring the role of silicone tape in promoting patient comfort and safety.

When it comes to industrial applications, cost-effectiveness is a crucial consideration. Single-sided silicone tape stands out as an affordable solution that does not compromise on quality. Unlike traditional adhesives, this tape provides a strong bond while being easy to apply, reducing labor costs and minimizing waste. Its versatile nature allows it to adhere to various surfaces, making it suitable for a wide range of industrial uses—from insulation to securing cables.

Furthermore, single-sided silicone tape boasts a long lifespan, which can save companies money in the long run. Its resistance to extreme temperatures and environmental factors means that it doesn't need frequent replacing, unlike other adhesive options. This durability not only contributes to a more efficient workflow but also reduces the overall operational costs associated with maintenance and material replenishment. As businesses look to optimize their operations and budget, incorporating single-sided silicone tape becomes a savvy move that aligns quality with economic sensibility.