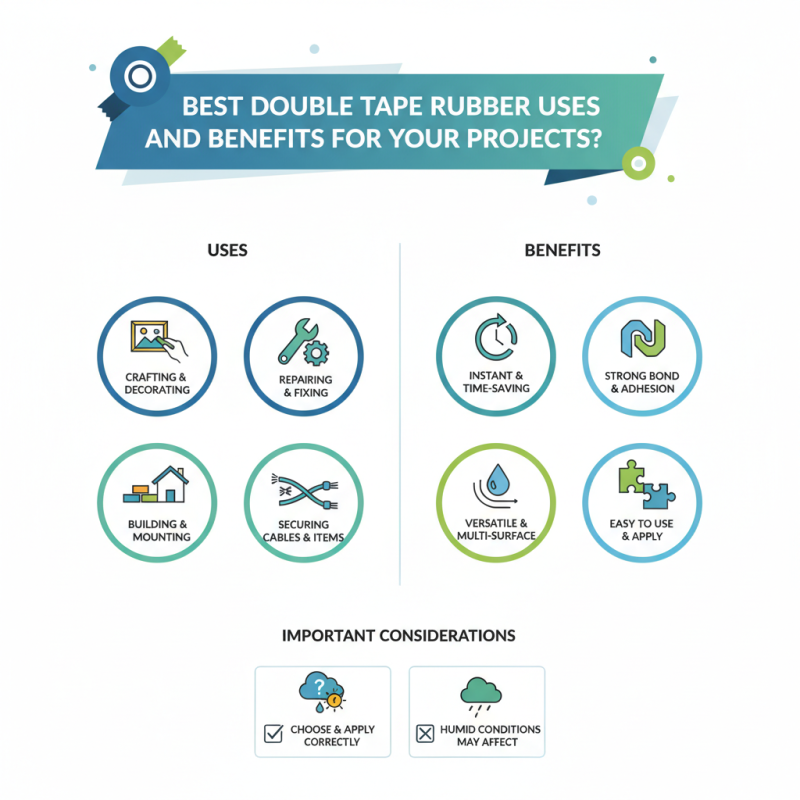

In recent years, the use of "Double Tape Rubber" has gained popularity in various projects. This versatile material offers multiple benefits that can enhance your tasks. Whether you are crafting, repairing, or building, Double Tape Rubber can be a reliable companion.

One of its main advantages is the ability to bond effectively to different surfaces. It creates a strong hold without the need for additional adhesives. Imagine fixing a loose item around your home or securing cables neatly — the applications are endless. The convenience of instant adhesion can save time and effort.

However, not all uses may turn out perfect. Sometimes, the tape might not adhere as expected, especially in humid conditions. Users must be aware of these factors. Understanding how to choose and apply Double Tape Rubber can help maximize its potential, while also providing room for improvement in your techniques.

Double tape rubber plays a crucial role in construction and manufacturing. Its unique adhesive properties provide excellent bonding strength for various materials, such as metal, wood, and plastic. This versatility makes it a go-to option for professionals. Workers use it for fastening, mounting, and sealing applications, enhancing the durability of their projects.

In construction, double tape rubber is often used for installing carpets and tiles. It ensures a secure fit and minimizes movement over time. In the manufacturing sector, it's vital for assembling parts and providing insulation against moisture. However, the effectiveness can vary based on surface conditions. Sometimes, the tape may not adhere as expected, requiring additional measures.

People often overlook the importance of proper surface preparation. Dust, oil, or moisture can hinder adhesion. Reflecting on experiences, many have encountered issues due to insufficient cleaning before applying the tape. Taking the time to prepare surfaces ensures better results and can prevent frustrating setbacks during projects.

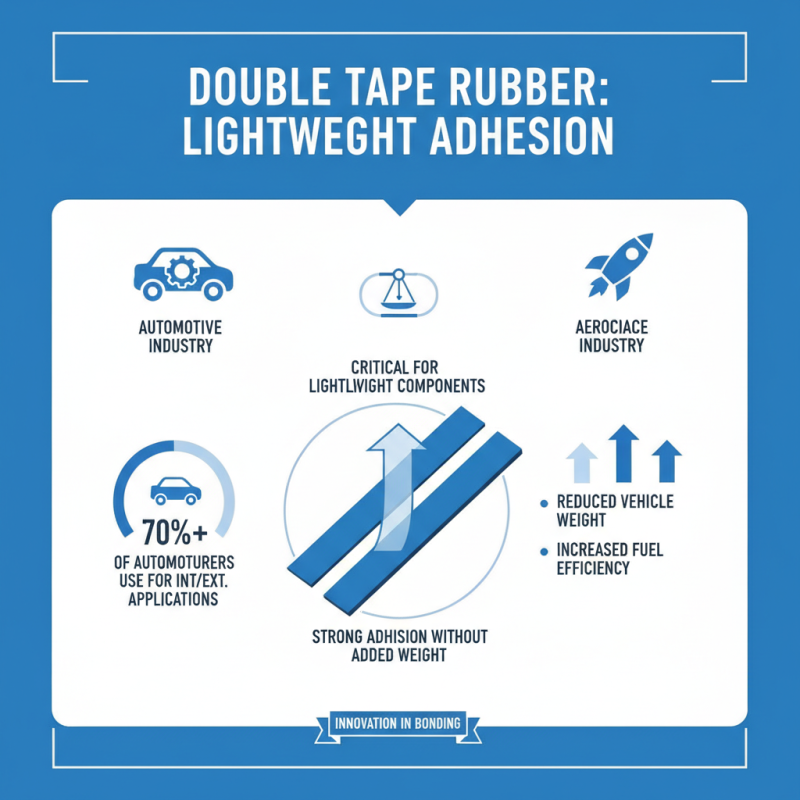

In the automotive and aerospace industries, double tape rubber is becoming increasingly important. Its lightweight nature provides significant benefits for components that require strong adhesion without added weight. According to recent industry reports, over 70% of automotive manufacturers now use double tape rubber for interior and exterior applications. This reduces the overall vehicle weight, increasing fuel efficiency.

One key advantage of double tape rubber is its ability to absorb vibrations. In the aerospace sector, for instance, double tape rubber can diminish noise levels in aircraft cabins. A study found that well-designed adhesive solutions can reduce noise by up to 10 dB. This not only enhances passenger comfort but also contributes to quieter operations during flight.

Tips: When working with double tape rubber, ensure the surface is clean and dry. This improves adhesion significantly. Keep in mind that improper application may lead to failure. The shift in usage from traditional bonding methods to double tape rubber, while beneficial, sometimes leads to challenges in consistency and strength. Testing is crucial before full-scale implementation.

Double tape rubber offers unique advantages over traditional adhesives in various projects. Its strong bonding capabilities make it ideal for both light and heavy materials. Unlike standard adhesives, double tape rubber does not need drying time. You can apply it and move on to the next step immediately. This can significantly speed up your workflow.

However, there are some considerations. Ensure the surfaces are clean and dry for optimal adhesion. If either surface is too rough, the tape may fail. Sometimes, you might encounter issues with peeling after some time. In such cases, reassess the surfaces you are working with. Preparation is essential here.

**Tips:** Always test a small area first. This will help you gauge the tape’s effectiveness on your particular materials. Consider the temperature and humidity, as they can impact adhesion. Keep double tape rubber in a cool, dry place to maintain its quality.

When considering double tape rubber for your projects, durability is key. Several factors impact its longevity. Environmental conditions play a significant role. High temperatures may degrade adhesive strength. Humidity can also weaken bonds over time. Protecting your project from these elements is essential.

Surface preparation affects how well the tape adheres. Clean and dry surfaces allow better bonding. Yet, many overlook this step, leading to failures. Thickness of the tape can influence durability. Thicker tapes often resist wear more effectively. However, remember that everyone may not need the thickest option.

Regular inspection of taped areas is advisable. This helps identify early signs of wear or failure. If not monitored, projects may suffer. Transparency in usage can lead to unexpected outcomes. It’s crucial to reflect on the choices made. Achieving the best results requires careful consideration and occasional adjustments.

When selecting double tape rubber for your projects, consider its intended use. Whether for home repairs or crafting, the type of surface matters. For uneven surfaces, opt for thicker tapes. They offer better adhesion and fill gaps effectively. Don’t underestimate the importance of choosing the right material. Some rubber tapes are more resilient in outdoor conditions, while others may suit indoor applications better.

Surface preparation is key. Clean surfaces thoroughly before application; this ensures stronger bonding. Sometimes, dust or grease can compromise the tape’s effectiveness. After applying, allow enough time for the tape to adhere properly. Rushing this process can lead to disappointment.

Trial and error is a part of the learning process. You might find that some tapes don’t work as well as expected. Keep a record of your experiences. Note what worked and what didn’t. This can be helpful for future projects. Double tape rubber can be versatile, but it requires thoughtful selection and application.