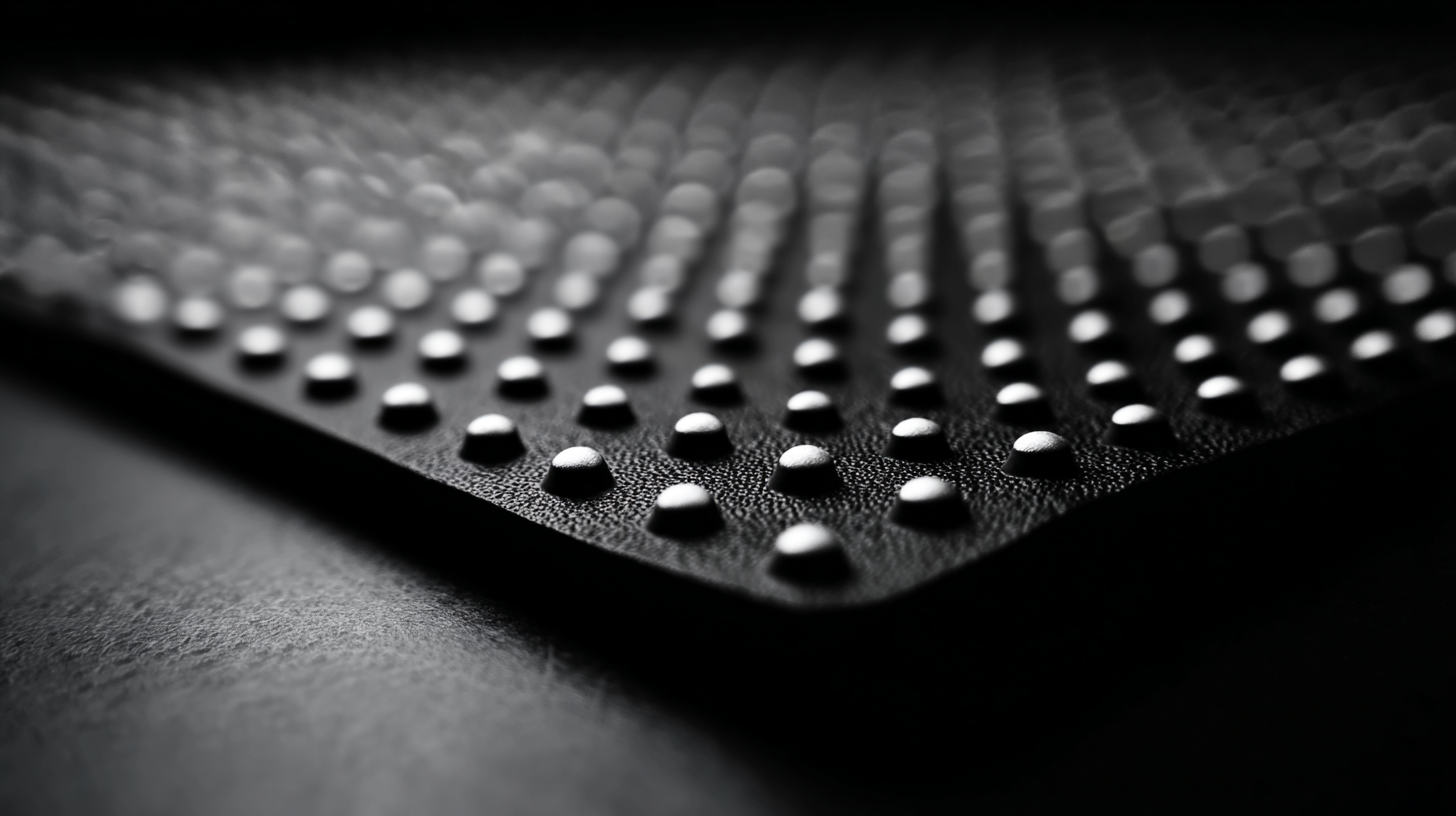

In the world of crafting and DIY projects, precision plays a pivotal role in achieving professional results. Silicone Adhesive Dots, a game-changing innovation from China, have emerged as a go-to solution for both enthusiasts and professionals alike. These small yet powerful dots are designed to provide a strong, durable bond for a wide range of materials, from paper and fabric to plastic and metal. Understanding the unique characteristics and applications of different types of Silicone Adhesive Dots is essential for maximizing their effectiveness in various projects. This blog will explore the distinct features and optimal uses of these versatile adhesive solutions, shedding light on how they can elevate your crafting experience and ensure global excellence in every creation. Whether you are a beginner or a seasoned pro, harnessing the potential of Silicone Adhesive Dots will undoubtedly enhance your creative endeavors.

Silicone adhesive dots are gaining momentum in various industries due to their unique properties and versatility. Notably, one of the key benefits is their ability to bond efficiently at high speeds, which is crucial in high-volume production environments. Recent advancements in micro-dispensing technologies have enabled the precise application of these adhesive dots, ensuring minimal waste while maximizing performance. This technology allows for consistent dispensing of the dots, enhancing the overall production efficiency by reducing downtime, as evidenced by recent reviews highlighting significant improvements in adhesive application methods.

Moreover, silicone adhesive dots offer remarkable durability and thermal stability, making them suitable for applications ranging from electronics to food packaging. The incorporation of bio-based additives in silicone formulations further enhances their performance attributes, promoting environmental sustainability while maintaining robust adhesion properties. Data from industry reports indicate that the market for silicone adhesives is expanding rapidly, driven by increasing demand across diverse sectors that require durable and effective bonding solutions. With their multifunctional capabilities, silicone adhesive dots are becoming indispensable tools for achieving excellence in manufacturing processes worldwide.

| Application Area | Benefit | Typical Use Case | Temperature Resistance | Color Availability |

|---|---|---|---|---|

| Craft and DIY Projects | Strong Bonding | Scrapbooking and home decor | -40°C to 120°C | Clear, White, Black |

| Medical Applications | Non-Toxic | Bandage securing | -50°C to 150°C | Transparent |

| Electronics | Electrical Insulation | Cable management | -40°C to 200°C | Various Colors |

| Automotive | Vibration Resistance | Assembling interior components | -40°C to 120°C | Black, Grey |

| Construction | Waterproofing | Sealing joints | -30°C to 100°C | Clear, White |

When selecting silicone adhesive dots, understanding the key factors can greatly enhance your choice and application outcomes. The market trends indicate a growing demand for high-quality adhesives, particularly in North America, where the market is projected to reach $19.35 billion by 2028. This highlights the importance of precision in manufacturing silicone adhesive dots, as their effectiveness will directly impact various industries ranging from construction to consumer goods.

Quality and compatibility are critical factors to consider when choosing silicone adhesive dots. Look for products that offer excellent adhesion capabilities, durability, and resistance to environmental factors such as moisture and temperature changes. Additionally, the source of the product matters; opting for silicone dots manufactured in regions known for rigorous quality standards can ensure you choose a reliable option. The growing trend in the global market underlines the necessity for consumers to be vigilant about the specifications and performance of silicone adhesive dots to achieve superior results in their projects.

The silicone adhesive market is witnessing significant growth, driven by the outstanding quality and precision offered by top manufacturers in China. As the global construction sector continues to expand, the Construction Silicone Sealants Market is expected to rise from USD 3.5 billion in 2021 to USD 4.5 billion by 2026, growing at a steady CAGR of 5.0%. This growth is indicative of the rising demand for reliable sealants that can withstand various environmental challenges, cementing China's role as a crucial supplier in the global market.

Additionally, the structural adhesives market is projected to reach USD 18.43 billion by the end of 2025, growing at a remarkable CAGR of 6.7%. This growth can be attributed to the increasing application of structural adhesives across industries such as automotive, aerospace, and construction. The ability of these adhesives to provide stronger and more durable bonds is key to their acceptance in critical structural applications. As the industry evolves, Chinese manufacturers are setting standards that resonate globally, ensuring that their products not only meet but exceed international expectations.

When it comes to crafting with silicone adhesive dots, precision and proper usage are key to achieving the best results. These adhesive dots are designed for a variety of applications, offering a clean and effective bonding solution for projects ranging from home decor to intricate DIY crafts. According to industry reports, the global silicone adhesive market is expected to grow significantly, driven by the increasing demand for high-performance adhesives in various sectors, indicating that silicone dots are not just a trend but a staple in the crafting world.

To maximize the effectiveness of silicone adhesive dots, follow these essential tips. First, ensure that the surfaces you are bonding are clean and dry; this will promote stronger adhesion. Secondly, apply the dots evenly and avoid overcrowding the area as this may lead to messy results. Lastly, give your project adequate time to cure as recommended by the manufacturer, which typically allows for optimal bonding strength.

Utilizing silicone adhesive dots properly can elevate your crafting game. Whether you're securing embellishments on a scrapbook page or attaching fabric pieces in sewing projects, these dots provide a hassle-free solution. For best practices, consider experimenting with different dot placements and weights to find what works best for your specific material combinations.

Silicone adhesive dots are rapidly gaining traction across various industries due to their versatility and superior bonding capabilities. According to a recent report by Transparency Market Research, the global silicone adhesive market is projected to reach USD 4.5 billion by 2026, driven largely by innovations in application techniques and material formulations. These adhesive dots, made from high-quality silicone, offer exceptional resistance to temperature fluctuations, moisture, and chemicals, making them ideal for diverse applications ranging from electronics to automotive sectors.

In the automotive industry, silicone adhesive dots are being utilized in the assembly of interior parts, such as dashboards and trim components, ensuring long-lasting durability and enhanced aesthetics. Moreover, in the electronics sector, they facilitate the secure mounting of components while providing vibration resistance and thermal stability. A study from MarketsandMarkets highlights that the demand for silicone adhesives in electronics alone is expected to grow at a CAGR of 8.5% from 2021 to 2026, underscoring the critical role these innovative solutions play in modern manufacturing processes. As industries continue to evolve, the adoption of silicone adhesive dots remains pivotal in fostering enhanced product performance and reliability.