Cold Silicone Glue has become a staple in various industries due to its versatility and reliability. According to a recent industry report by Grand View Research, the global adhesives market is projected to reach $55.3 billion by 2028. This growth highlights the increasing demand for effective bonding solutions. Cold Silicone Glue stands out for its unique properties. It cures at room temperature, making it safer and easier to use than hot adhesives.

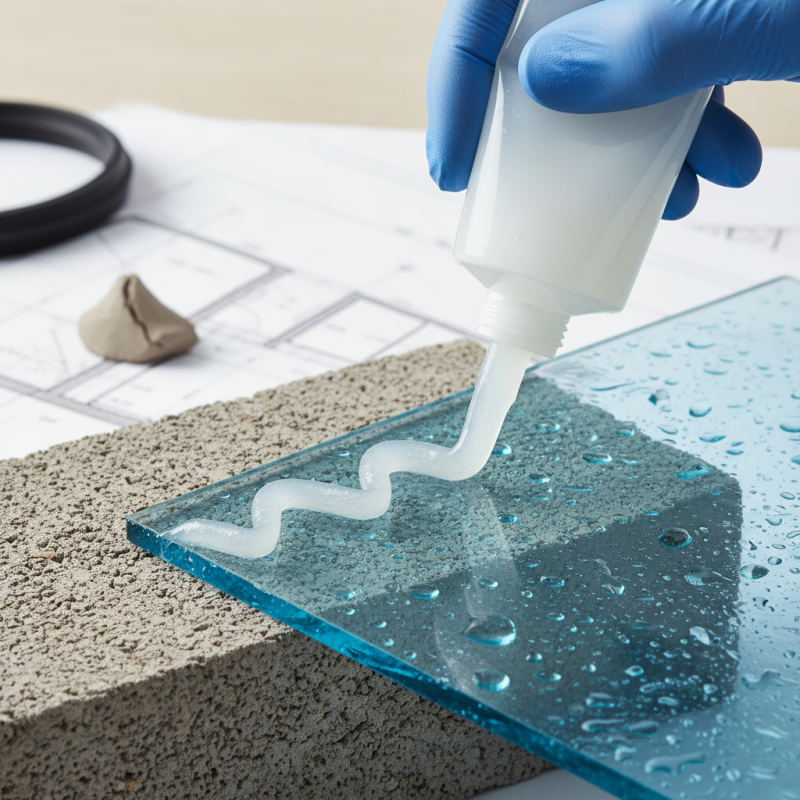

Professionals favor Cold Silicone Glue for its waterproof capabilities. Research shows that water-resistant adhesives account for over 30% of the market. This feature is essential for outdoor projects or items that face moisture. Additionally, Cold Silicone Glue maintains flexibility, allowing for movement without cracking. However, it’s crucial to consider the time it takes for curing. Some may find it slower than other adhesives, which requires careful planning.

Despite its advantages, Cold Silicone Glue isn't suitable for every application. Users must assess bonding surfaces and conditions. The choice of adhesive can significantly impact the project's success. Understanding these factors can lead to better outcomes, ensuring that Cold Silicone Glue serves its purpose effectively.

Cold silicone glue offers unique advantages for a variety of projects. This adhesive is known for its strong bonding capacity. It adheres well to many materials, including wood, metal, and plastic. Even in challenging environments, its water-resistant properties remain effective. This makes it suitable for both indoor and outdoor applications, where durability is essential.

Another benefit is its flexibility. Cold silicone glue remains pliable after curing, allowing materials to move without breaking the bond. This is particularly useful in projects involving natural movements, such as wooden furniture. However, users should be careful. Applying too much glue may result in excess that needs to be cleaned up later, which can be frustrating.

Quick curing times are another plus, but there can be drawbacks. If not handled promptly, the surface can become tacky. It’s essential to work efficiently and monitor the drying process closely. Some may find that getting the application just right can take practice. Mistakes are common but can lead to improved techniques over time. Being patient and observing how the glue interacts with different materials will yield better results in future projects.

When choosing an adhesive for projects, cold silicone glue often stands out. It offers flexibility and strong bonding. Compared to traditional glues, cold silicone glue is ideal for uneven surfaces. Its ability to remain flexible prevents cracking, making it suitable for both indoor and outdoor use. However, it can take longer to set fully, which may test your patience.

In contrast, other adhesives like epoxy or hot glue set quickly but lack flexibility. Epoxy provides a rigid bond, while hot glue can become brittle over time. Cold silicone glue allows for a slight movement in joints, which can be advantageous in high-stress areas. It remains waterproof and resistant to extreme temperatures, unlike most other adhesives.

Choosing the right adhesive can be confusing. Each type has strengths and weaknesses. Cold silicone glue's unique traits can serve various projects well. Yet, it may not always be the best fit for every application. Sometimes, trying different types can lead to better results. Experimentation is key when adhering materials together successfully.

Cold silicone glue has emerged as a versatile solution across various industries. Its applications are broad, catering to fields such as construction, automotive, and electronics. In the construction industry alone, the adhesive market is projected to reach $50 billion by 2027, driven largely by the demand for durable bonding agents like cold silicone glue. This adhesive is preferred due to its flexibility and resistance to environmental factors, making it ideal for sealing windows and joints.

In the automotive sector, cold silicone glue is critical for assembling components. Reports estimate that over 30% of automotive manufacturers employ silicone adhesives for their lightweight properties. They contribute to fuel efficiency by reducing overall vehicle weight. Moreover, these glues perform well in extreme temperatures, which is vital for vehicle durability. However, the application process can be tricky. Improper surface preparation may lead to bond failures, highlighting the importance of careful application techniques.

The electronics industry also benefits from cold silicone glue, especially in waterproofing and insulating components. A recent study indicated that silicone adhesives account for approximately 25% of adhesive use in this sector. Despite their benefits, issues like curing time can pose challenges for high-speed production lines. Users must carefully assess their adhesive choice based on project demands.

| Industry | Application | Benefits |

|---|---|---|

| Construction | Sealing joints and gaps | Flexible, water-resistant, and durable |

| Automotive | Windshield bonding | High adhesion and resistance to vibrations |

| Electronics | Insulating and bonding components | Non-corrosive and heat resistant |

| Arts and Crafts | Assembling mixed materials | Clear drying option available for aesthetic projects |

| Medical | Sealing medical devices | Non-toxic and safe for sensitive applications |

Cold silicone glue has gained popularity due to its environmental benefits. It is a solvent-free adhesive. This means fewer volatile organic compounds (VOCs) are released into the air. According to the Environmental Protection Agency (EPA), VOCs contribute to air pollution. By using cold silicone glue, you are reducing your carbon footprint.

Safety is another important aspect. Cold silicone glue is non-toxic. Users do not need to worry about harmful fumes or skin irritations. A study by the National Institute for Occupational Safety and Health highlights that many traditional adhesives can cause respiratory issues. In contrast, cold silicone glue provides a safer alternative.

Tips: Always work in a well-ventilated space. Even though cold silicone glue is safer, proper ventilation helps mitigate any risks. When applying, wear gloves to protect your skin, even if you are not allergic. Regularly check your adhesive supplies to ensure they meet safety standards.

In practice, some users find it challenging to achieve desired curing times. It requires patience and attention. Each project may need different conditions for optimal adhesion. It’s important to read the specifications carefully. Adjust your approach based on your materials and environment for successful bonding.

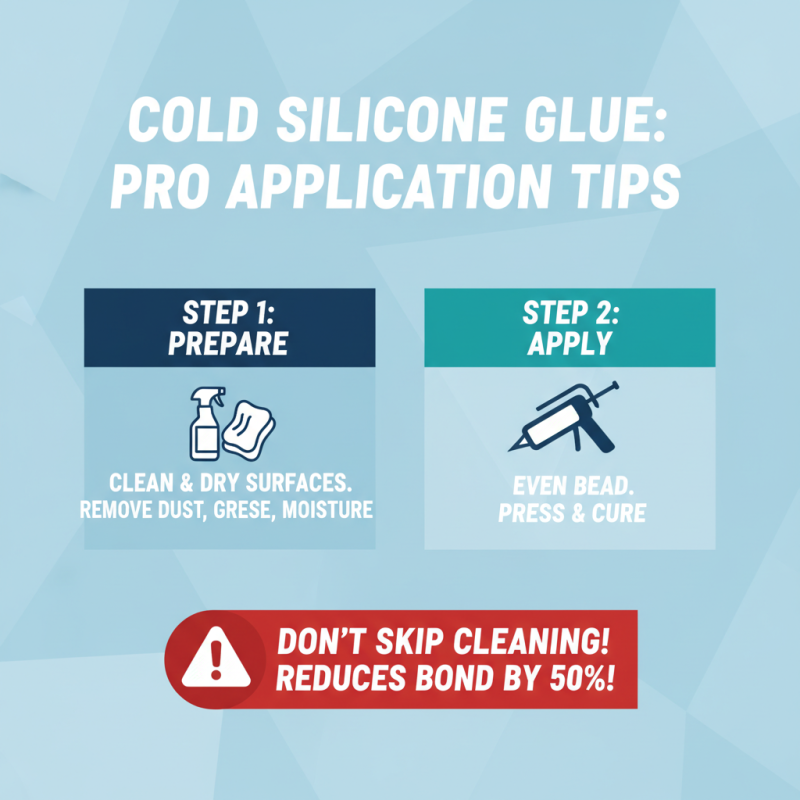

Cold silicone glue offers a powerful solution for various projects. To achieve optimal results, proper application is essential. Begin by ensuring the surfaces are clean and dry. Dust, grease, or moisture can hinder adhesion. A report from the Adhesive and Sealant Council reveals that improper surface preparation may reduce bond strength by up to 50%. This emphasizes the importance of a thorough cleaning process.

When applying cold silicone glue, utilize a caulking gun for precision. Apply an even bead along the joint or surface. Small, consistent lines promote better adhesion and reduce waste. A study by the International Journal of Adhesion and Adhesives noted that uneven application could result in weak spots, leading to potential failures. After applying, consider tooling the bead with a spatula for a smooth finish. This not only improves the appearance but also strengthens the bond by pushing the glue into the surfaces.

Be cautious of excess glue. While it may seem tempting to use more, this can lead to messy results and longer curing times. The ideal curing time for most cold silicone products varies, but avoiding humidity and temperature extremes can enhance performance. Evaluate your application techniques regularly. Over time, you may identify ways to improve your method for better efficiency and bond strength.