Choosing the right adhesive is crucial for any project. Double Tape Rubber stands out for various reasons. This versatile material offers strong bonding and easy application.

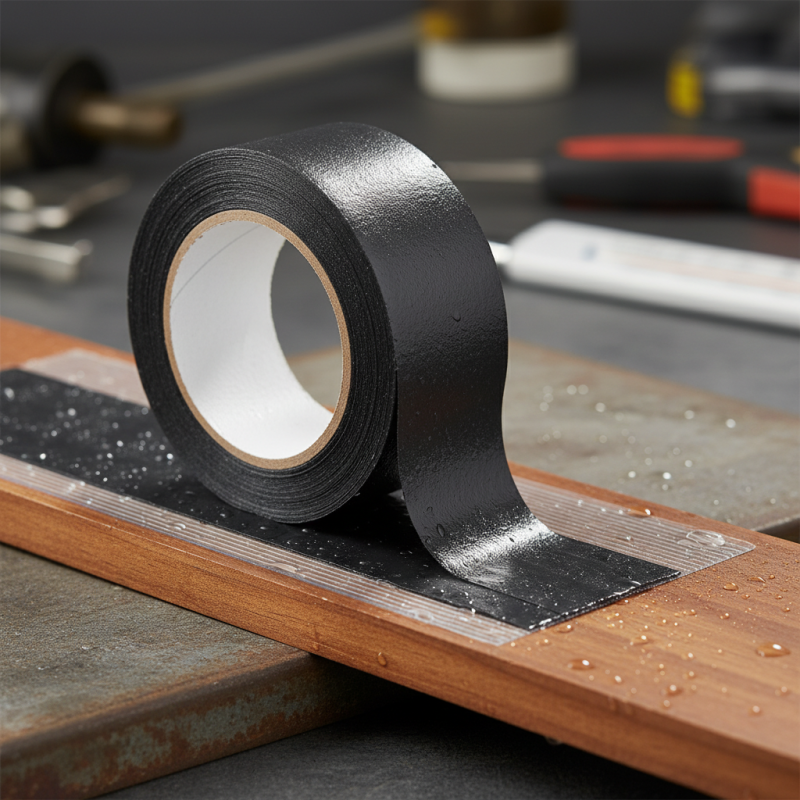

Double Tape Rubber creates a lasting hold on diverse surfaces. It works well on metal, wood, and plastics. Users appreciate its resistance to moisture and temperature. For indoor or outdoor use, this tape performs reliably. However, selecting the right thickness can be challenging for some.

In the world of adhesives, Double Tape Rubber is often overlooked. Many may question its effectiveness. Yet, those who choose it recognize its unique qualities. It’s essential to experiment with different options to find the best fit. Ultimately, Double Tape Rubber can simplify your adhesive needs.

Double tape rubber has gained popularity in various adhesive applications due to its unique advantages. This type of adhesive offers strong bonding capabilities, making it ideal for both household and industrial uses. Its flexibility allows it to securely attach different materials, including paper, plastic, and metal. Users appreciate its ease of use and the reliable performance it delivers.

One significant benefit of double tape rubber is its resistance to moisture. This feature makes it suitable for environments where humidity is a concern. The tape maintains its adhesive properties, even when exposed to damp conditions. It is important to test adhesive strength in extreme conditions. Sometimes, the bond may weaken unexpectedly.

When using double tape rubber, consider the surface preparation. Clean the surfaces thoroughly to enhance adhesion. Dirt or grease can hinder the bonding process. Additionally, apply consistent pressure when sticking the tape down. This ensures a stronger, more durable bond. Always remember, the thickness of the tape can impact its effectiveness. A thicker tape generally offers more cushioning and support, but may not be suitable for all applications.

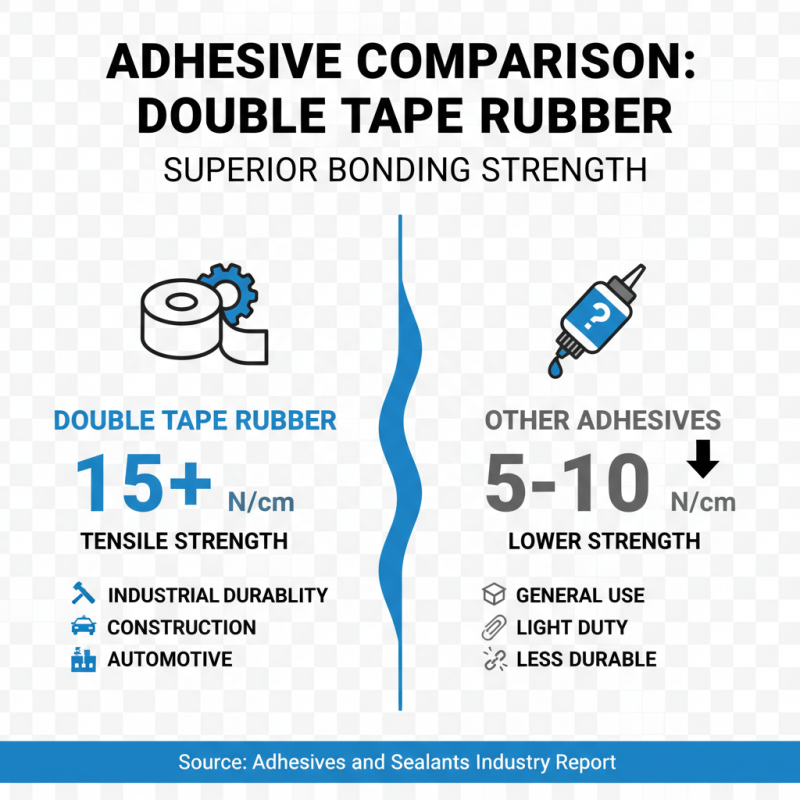

When comparing double tape rubber to other adhesive options, several factors stand out. Double tape rubber offers superior bonding strength. According to a report from the Adhesives and Sealants Industry, it provides a tensile strength that can exceed 15 N/cm. This is crucial for applications where durability matters, such as construction and automotive industries.

On the other hand, traditional adhesives, like liquid adhesives, often require longer curing times. This can slow down production efficiency. In contrast, double tape rubber allows for immediate use after placement. However, some users have reported challenges with temperature sensitivity. Exposure to extreme conditions can affect adhesive performance, raising concerns for outdoor applications.

In terms of versatility, double tape rubber shines. It adheres well to various surfaces, including metal, plastic, and wood. Yet, not every project will benefit from it. Certain materials may require specialized adhesives to achieve desired results. Ultimately, users must weigh these factors carefully. The choice between double tape rubber and other options should reflect specific needs and environments.

Double tape rubber has gained popularity in various adhesive applications due to its unique characteristics. High-quality double tape rubber is known for its strong adhesion and versatility. This material can bond with different surfaces, including metal, plastic, and wood. According to a 2022 market analysis, double-sided tape usage in various industries increased by 30% in the past five years, showcasing its growing importance.

One significant feature of double tape rubber is its durability. It can withstand temperature fluctuations and significant wear and tear. Reports indicate that well-designed double tape rubber can last up to ten years under ideal conditions. This longevity makes it a cost-effective choice for long-term projects. However, not all double tapes are created equal, and inconsistencies in quality can lead to adhesive failure. Users may find some products falling short of their promises.

Additionally, double tape rubber offers excellent conformability. It can adhere to irregular surfaces, which is crucial in construction and automotive applications. However, there's a downside. In humid environments, some double tapes may lose their grip. A recent study highlighted that approximately 15% of users in marine applications reported adhesion issues after prolonged exposure to moisture. Therefore, proper selection based on environmental conditions remains essential. Choosing double tape rubber requires careful consideration to avoid potential pitfalls.

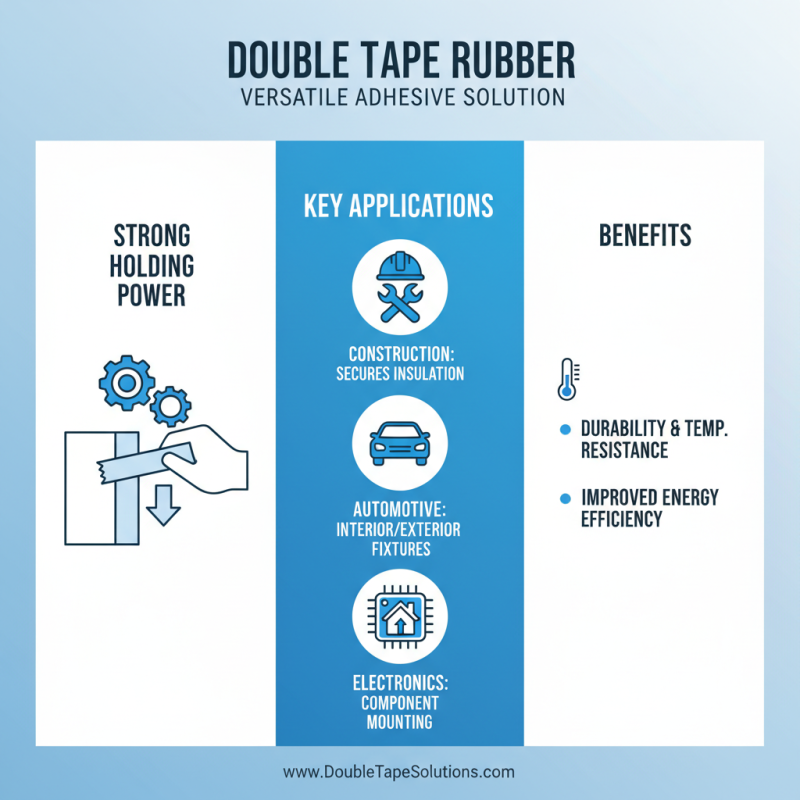

Double tape rubber is a versatile adhesive solution found in various industries. Its strong holding power makes it ideal for construction, automotive, and electronics. In construction, professionals often use it to secure insulation materials. It provides durability and resistance to temperature changes. This can lead to improved energy efficiency in buildings.

In the automotive sector, double tape rubber is used for attaching trim and moldings. It can withstand vibrations and temperature fluctuations, making it perfect for vehicle interiors. Similarly, in electronics, this adhesive holds components firmly in place. It supports various devices, ensuring reliability and proper functioning.

However, not every application will yield the desired results. Surface preparation is crucial. If the surfaces are dirty or uneven, adhesion might suffer. Users must carefully consider environmental factors too. Moisture and temperature can interfere with performance. Despite these potential drawbacks, double tape rubber remains a popular choice in many industries. Its adaptability and strength often outweigh these concerns.

When applying double tape rubber, surface preparation is key. Clean the surfaces thoroughly to remove dust and grease. Use a cloth and some mild detergent for cleaning. Dry the surfaces completely before application. This step is crucial for good adhesion. Even a small amount of residue can weaken the bond.

Next, measure and cut the tape precisely. Overlapping the tape can lead to air pockets and reduced durability. Press the tape firmly onto the surface, ensuring there are no bubbles. A roller can help with even pressure. Be cautious; if you apply it incorrectly, you may need to start over.

Lastly, let the adhesive cure properly. This often requires patience, as rushing this step can lead to failure in the bond. If the tape does not hold, take a moment to reflect on what went wrong. Adjust your technique for better results in the future. Each application can be a learning experience, enhancing your skills over time.

| Advantages | Applications | Considerations | Tips for Application |

|---|---|---|---|

| Strong adhesion | Craft and DIY projects | Surface preparation is crucial | Ensure surface is clean and dry |

| Flexible and durable | Automotive applications | Temperature resistance | Apply pressure evenly |

| Water resistant | Home repair and maintenance | Compatibility with materials | Let it cure properly |

| Easy to cut and apply | Electronic repairs | Thickness may affect performance | Use a sharp blade for cutting |