In the ever-evolving landscape of adhesive technologies, Double Tape Rubber has emerged as a vital component across various industries. As we approach 2025, understanding its diverse applications is more critical than ever. Industry expert, Dr. Emily Johnson, a leading figure in adhesive research, emphasizes, "Double Tape Rubber is not merely a tool for adhesion; it’s an innovative solution that empowers industries to enhance efficiency and sustainability." This introduction illustrates the significance of double tape rubber, showcasing its potential to revolutionize how we approach bonding tasks.

The unique properties of Double Tape Rubber make it applicable in numerous fields, from construction to automotive and even electronics. Its versatility and effectiveness help businesses streamline production processes while reducing waste and costs. As technological advancements continue to unfold, the benefits and uses of Double Tape Rubber are set to expand, paving the way for more sustainable practices and greater resilience in our manufacturing methodologies. In this article, we will explore the top ten uses and benefits of Double Tape Rubber that you need to know in 2025, shedding light on why this material is becoming indispensable for businesses worldwide.

Double tape rubber, commonly known for its strong adhesive properties, is a versatile material made from a blend of rubber compounds and adhesives. This unique composition allows for effective bonding to various surfaces, making it an integral component in multiple applications ranging from household repairs to industrial uses. The rubber base provides flexibility and durability, while the adhesive layer ensures a reliable grip, even under stress or varying environmental conditions.

Understanding the specific types of rubber used in double tape is crucial, as they can greatly influence performance. Natural rubber offers excellent elasticity and resistance to abrasion, while synthetic rubber might be used for enhanced weather resistance and temperature tolerance. The exact formulation can vary, with some double tape rubbers containing additives to improve qualities such as UV resistance and chemical stability. This combination of properties makes double tape rubber not only effective but also adaptable to a wide range of tasks, providing solutions where traditional adhesives may fail.

Double tape rubber is becoming increasingly popular in household applications due to its versatility and strong adhesive properties. One of the most common uses of double tape rubber is for mounting items around the home. Whether it's hanging pictures, affixing decor, or securing small shelves, this double-sided tape provides a reliable hold, making installation effortless and mess-free. It is also great for organizing cords and cables, allowing for a tidy and clutter-free environment.

Tips: When using double tape rubber for hanging, make sure the surfaces are clean and dry to ensure the best adhesion. For heavier items, it's wise to use multiple strips for added support.

In addition to mounting, double tape rubber is ideal for repairs. It can effectively seal leaks or damages in household items without the need for additional tools. From fixing loose furniture parts to repairing torn fabrics, its strong bond ensures durability. Moreover, it can serve as a temporary solution for various household needs, making it an indispensable item in any toolbox.

Tips: For repairing fabrics, cut the double tape rubber to fit the damage area and press it firmly; this will prevent fraying and extend the item's life. Always test on a small area to ensure it does not damage the surface.

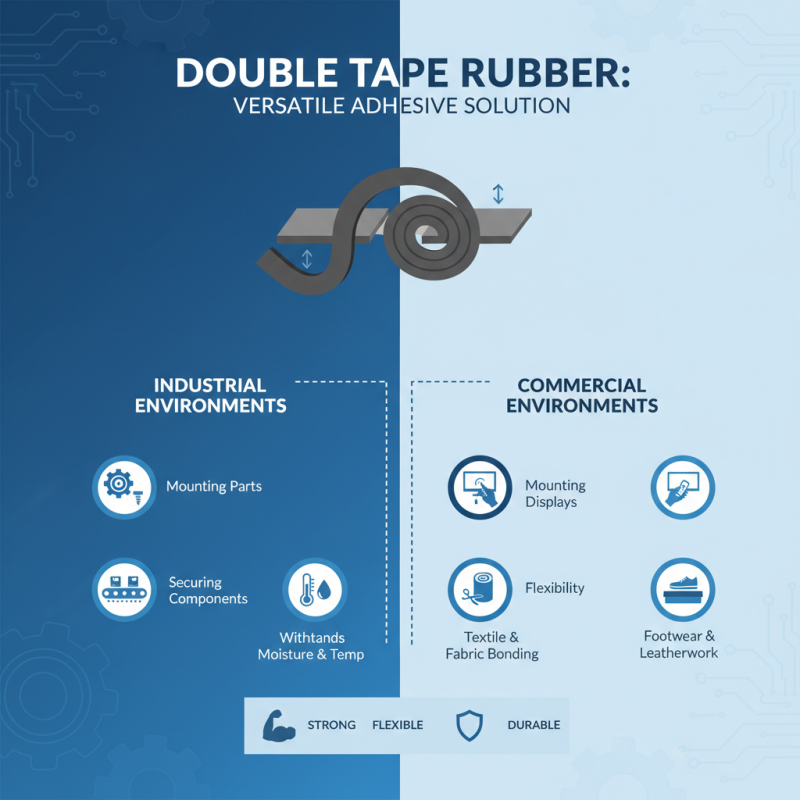

Double tape rubber, a versatile adhesive solution, is making significant strides in both industrial and commercial environments. This material is favored for its strong adhesion, flexibility, and durability, which makes it suitable for a plethora of applications. In manufacturing settings, double tape rubber is commonly used for mounting parts, securing components in assembly lines, and providing insulation. Its ability to withstand various conditions, such as moisture and temperature fluctuations, further enhances its utility in diverse industrial practices.

In the commercial sector, double tape rubber serves as an excellent solution for signage, displays, and promotional materials. Its ease of application allows businesses to quickly set up and rearrange displays without the need for additional tools or materials. Good adhesion ensures that signs remain fixed in place, while the clean removal properties reduce damage during tear-downs or relocations.

Tips: When using double tape rubber, always clean the surfaces to be bonded for optimal adhesion. Additionally, consider the weight of the items being mounted; heavier objects may require reinforced tape or additional support. Lastly, test the tape on a small area first to ensure it does not damage the underlying surface, ensuring a smooth application process.

Double tape rubber has emerged as a must-have material for craft and DIY enthusiasts in recent years, and this trend is expected to grow significantly by 2025. According to the Market Research Future report, the global adhesive tape market is projected to reach 77 billion USD by 2025, primarily driven by the increasing demand for versatile and durable materials in various sectors, including crafting and home improvement. Double tape rubber stands out for its ability to create strong, long-lasting bonds while being easy to use and apply. This type of tape is especially valuable in projects where precision and durability are paramount, as it adheres quickly to different surfaces without leaving behind residue.

One of the key benefits of double tape rubber for DIY and craft projects is its superb flexibility. This material can easily conform to various shapes and sizes, making it ideal for intricate designs that require a neat finish. Whether it’s securing decorative elements on a scrapbooking project or mounting lightweight objects in home décor, users can trust that double tape rubber will provide a robust hold. Furthermore, a study in the Journal of Adhesion Science and Technology indicates that double tape rubber offers superior moisture resistance compared to traditional adhesive options, ensuring that completed projects remain intact even in humid conditions. As we look toward 2025, the applications of double tape rubber in crafting are not just expanding; they are revolutionizing how enthusiasts approach their artistic endeavors.

The world of double tape rubber is witnessing a significant transformation, driven by innovative applications and emerging trends. One notable trend is the increased focus on sustainable materials. As industries strive for eco-friendliness, manufacturers are developing double tape rubber from biodegradable and recycled materials, reducing environmental impact while maintaining performance. This eco-conscious shift not only meets regulatory requirements but also appeals to consumers who prioritize sustainability in their purchasing decisions.

Another key development in double tape rubber applications is its integration into smart technologies. With the rise of smart homes and IoT devices, double tape rubber is being engineered to incorporate sensors. This innovation allows for real-time monitoring and feedback in various applications, enhancing user experience and functionality. As these technologies evolve, the adhesive properties of double tape rubber are being paired with advanced electronics to create seamless and effective solutions in fields such as health care, automotive, and home automation.

Furthermore, advancements in manufacturing processes are leading to the creation of specialized double tape rubber that can withstand extreme conditions, such as high temperatures or moisture saturation. Such improvements widen the scope of potential applications, including in aerospace, construction, and marine industries, where reliability and durability are paramount. As these trends continue to shape the landscape of double tape rubber, the focus on performance enhancement and adaptability will serve as a cornerstone for future innovations.